Problem

In smaller companies, many production processes in joining technology are still carried out manually, since a higher degree of automation is often not economical. Partial automation of welding workstations offers great potential for increasing efficiency and process capability as well as reducing production costs.

Objectives

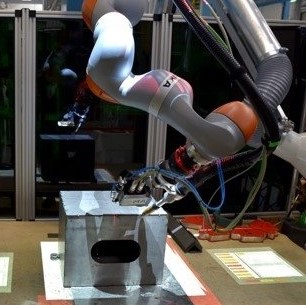

Human-robot cooperation (HRC) is an approach to demand-oriented, adapted and, if necessary, temporary automation. The central element of a partially automated robot welding workstation is the development of a new user interface that enables the intuitive adaptation of a robot system in the overall production process.

Approach

The production system developed at ZeMA enables quick and easy setup of the robot cell to meet the challenges of assembling customized product solutions. Thanks to the newly developed measurement concept, the robot system can be quickly put back into operation after a modification, which reduces the downtime of the assembly cell and increases the productivity of the plant.

Areas of application

This technology is used in the areas of special machine construction as well as in contract manufacturing.