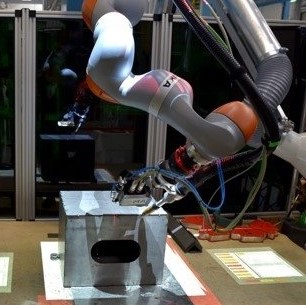

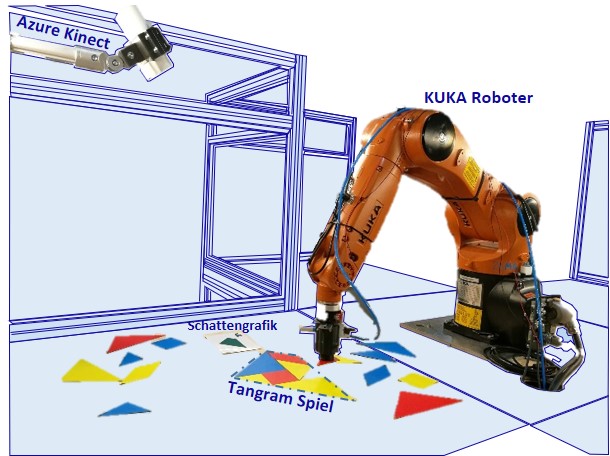

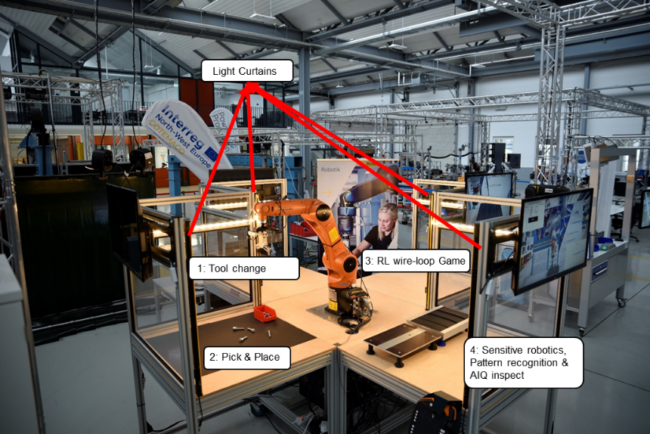

Partially Automated Robot Welding Station (ZeMA)

Problem In smaller companies, many production processes in joining technology are still carried out manually, since a higher degree of automation is often not economical. Partial automation of welding workstations offers great potential for increasing efficiency and process capability as well as reducing production costs. Objectives Human-robot cooperation (HRC) is an approach to demand-oriented, adapted…