Motivation:

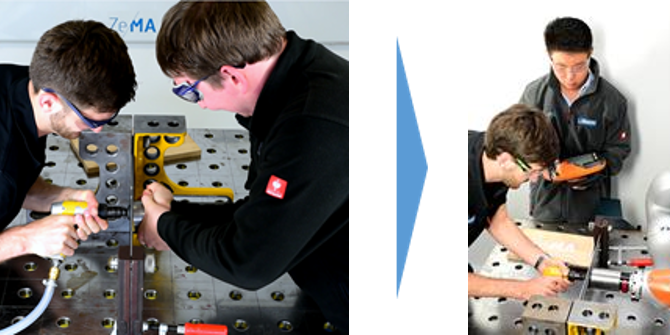

Riveting is an important joining process in aircraft assembly. However, the working conditions for operators during manual riveting process can be mediocre. A semi-automatic human-robot collaboration riveting process is proposed. It mandates an operator to handle the riveting hammer and to insert rivets; and a robot to operate the dolly. Using an impedance mode, the robot has successful upset a rivet shank into a formed head. This process has been validated experimentally. Further research is needed to optimize this technology.

Status:

A semi-automatic riveting process based on the principles of human-robot collaboration was developed. A state of the art research including a theoretical part and an experimental manual riveting has been established. Based on this, a semi-automatic riveting sequence was designed and tested. The resulting rivets are conform to the industry specifications in terms of height, diameter and overall appearance. Further studies will be carried on the human-robot collaboration riveting process.